Webinar

Corrosion control: predictive power play with Monte Carlo simulation

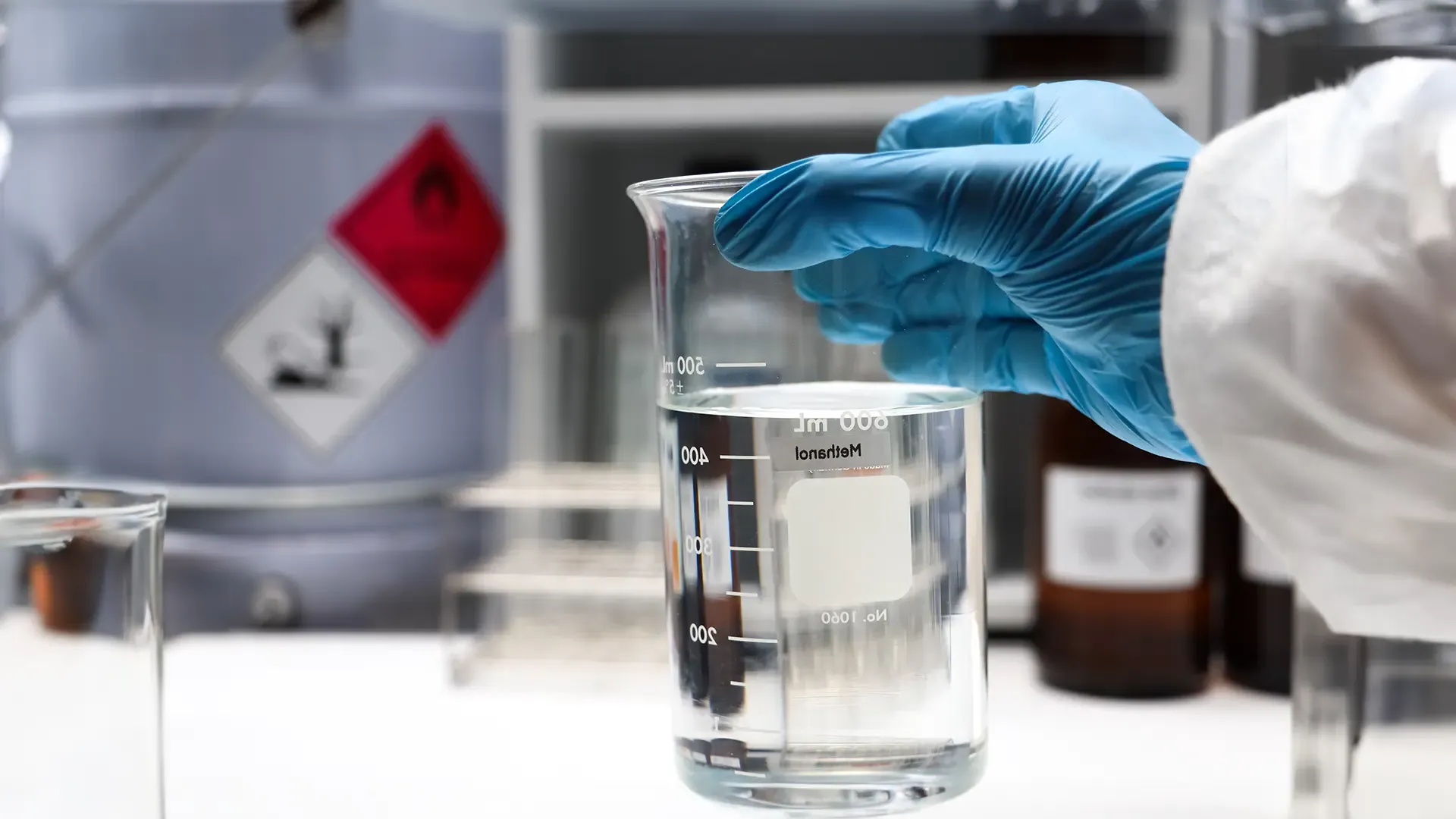

Methanol is one of the most widely produced organic chemicals and important raw materials in the chemical industry. It’s a building block for hundreds of everyday products including solvents, pharmaceuticals and fuel.

Conventional methanol is produced using fossil fuels, releasing intensive greenhouse gases. When methanol is produced using carbon neutral energy sources, such as recycled CO2, biomass and hydrogen electrolysers, it is categorised as e-methanol.

Incredibly versatile in nature, e-methanol can be used to unlock the full fuel and chemical value chain and provides chemical producers with a sustainable production alternative.

We provide end to end engineering services for e-methanol production facilities, starting with feasibility studies through to engineering, procurement, construction management and assistance to start-up of plant.

Feasibility studies

Engineering

Procurement

Construction management

Start up

For more than thirty years, we have supported the traditional methanol market, leveraging decades of fossil fuel and chemical production experience.

Our traditional energy sector heritage and deep experience in electrolyser and carbon capture technologies coupled with our and knowledge of the best technology licensors, ensure we are well positioned to support at every stage of an e-methanol project.

We play the important role of integrator and can manage the sometimes challenging integration of existing and new chemical plant infrastructure, bringing all elements together to ensure efficient, safe and sustainable production.

From Sweden to Uzbekistan, we are delivering complex methanol and e-methanol projects at every stage of the project life cycle. We collaborate with clients and follow the project from early studies to unit start up, including the top technology licensors and innovation.